August 18, 2020 – Clobotics Holdings today announces it has acquired Denmark based Finetune ApS, a leading technology solution provider for the wind power sector with a focus on blade technology, software development and data science in wind turbine O&M and performance optimization.

“With the continuous collection of blade data and deep integration of our inspection service with our wind customers’ operations, we see a great opportunity to further help our customers analyze and monetize their data and expand along the value chain of wind operations and maintenance” said George Yan, CEO of Clobotics. “Since last year, our wind team has been working with Finetune in the development and commercialization of blade repair technologies and machine learning-based turbine SCADA data analytics. We are impressed by their industry knowledge and expertise.”

Finetune was founded in 2017 and offers novel technology solutions in blade defect evaluation, turbine digital twin, power prediction and blade manufacturing.

“Ever since I had the first chat with George back in 2019 there has been no doubt that Clobotics and Finetune share the same vision. We see the acquisition of Finetune as the best possible opportunity for getting Finetune’s cutting edge technology to use and bring value to customers in the wind industry” said Lennart Kuhlmeier, CEO of Finetune. “We are looking very much forward to the years to come where we will do our part to push Clobotics even further into a profitable business with a solid leading technology position.”

“When it comes to the blade surface, knowledge literally is power. We look forward to integrating with Clobotics’ artificial intelligence, data science and hardware capabilities to bring down the cost of wind turbine operations and maintenance and raise power production” said Wout Ruijter, CTO of Finetune.

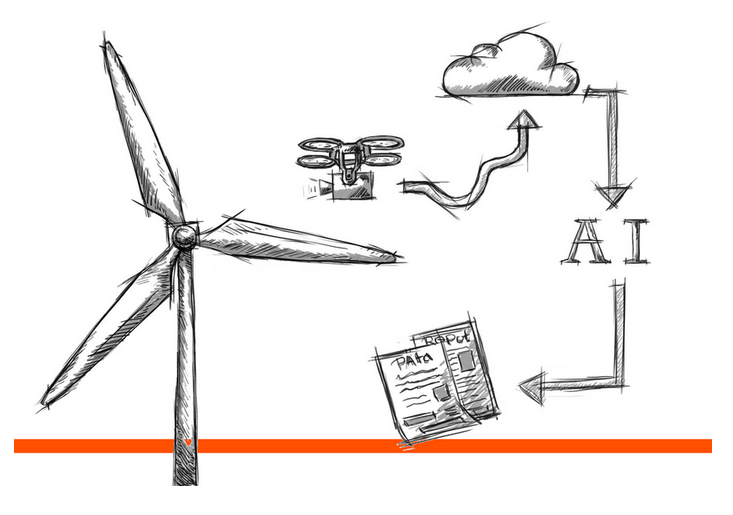

Clobotics, with teams based in Esbjerg, Seattle and Shanghai, has a strong track record in drone-based inspection of wind turbines and AI-based analysis of the resulting images. Its technology allows faster, safer, and lower-cost inspections as well as high-quality reporting delivered faster than any alternative on the market.

After closing, Finetune team will join Clobotics’ global wind R&D platform. As Principal Wind Engineers, Dr. Kuhlmeier and Dr. Ruijter will lead the research and technology development in blade repair and turbine data analytics areas. These two areas are the future growth drivers of the wind division and will have significant synergies with Clobotics’ existing business and technology strengths.

Combined, Clobotics will be able to disrupt the huge but labor-intensive wind repair market by leveraging strong automation and analytical capabilities. More importantly, it can not only offer full-stack solutions from inspection to repair to data analytics covering the full blade operations and maintenance value chain but also broaden its total addressable market.

About Clobotics

Clobotics is a global leader in AIoT solutions for the wind power and retail industries. Clobotics’ end-to-end solutions combine computer vision, artificial intelligence/machine learning, and data analytics software with different hardware form factors, including autonomous drones, mobile applications, and other Internet of Things devices to help companies automate time-intensive operational processes, increase efficiencies, and boost the bottom line through the use of real-time, data-driven insights and analysis. Clobotics was named the CNBC Upstart 100 List in 2018 and was highlighted as an important computer vision solution provider for the industrial sector in the latest Bloomberg NEF report on computer vision. To learn more, visit www.clobotics.com

About FineTune

Finetune helps leading wind industry players get the most out of their assets through AI based solutions for performance and maintenance optimization. In our team we have experienced subject matter experts within wind turbine blade technology, software development, data science and AI. We have in-house software and know-how that allows us to quickly build AI based systems for wind power issues, be they in manufacturing, O&M, or performance optimization.

About Dr. Lennart Kuhlmeier

- Mechanical engineer with focus on composites and structural design

- Chief Engineer at Suzlon and Head of Design at SSP Technology and Nordex

- Worked at Vestas, Suzlon, Envision, SSP Technology and Nordex since 2001 in various areas of blade design and blade manufacture processes

About Dr. Wout Ruijter

- Mechanical engineer with focus on composites and fluid mechanics

- Worked at Vestas to design blades and write modelling tools for blades in structures and aerodynamics.

- Worked at Envision and MHI Vestas Offshore on blade design, design software and leading-edge repair methods