Filter

In the Press

Clobotics Wind Services Announces Its New Clobotics Crawler™ Robot

Purpose-built for visually inspecting the inside of wind turbine blades Clobotics Wind Services announces availability of its Clobotics Crawler™ (code named KIWI) robot – a device purpose-built for safely, rapidly and cost-effectively documenting the internal condition of wind turbine blades. The device features two high resolution, high dynamic range (HDR) cameras, LED lighting, and a […]

In the Press

Announcing Clobotics IBIS™ 4.8

New release improves speed, cost and quality of external visual blade inspections Clobotics Wind Services is now shipping the latest version of its autonomous drone-based inspection system. The 4.8 release of Clobotics IBIS™ leverages the newly released Sony ILX-LR1 commercial camera, along with numerous mechanical and software improvements to deliver a state-of-the-art combination of speed, […]

In the Press

2023 End of Year Review

It’s time, once again, for our End of Year Report – aggregate global statistics drawn from our Clobotics IRIS portal system for organizing, analyzing and presenting blade inspection and repair information. This year, we look back on nearly 40,000 wind turbines worth of inspections conducted in 2023 across every region of the globe. This brings […]

In the Press

Scaling Up Blade Inspections in Brazil: A Case Study

Brazil is one of the five largest wind markets in the world and growing fast. In the last decade, Brazil has gone from 2.5 GW of installed wind power capacity in 2012 to 22 GW in 2022. Since 2017, ArthWind has helped wind site managers use inspection data to drive their maintenance decision making. As […]

In the Press

2022 End of Year Review

We recently completed our look back on a very successful 2022 inspection season around the world. Across our global regions, we inspected over 32,000 wind turbines bringing the cumulative total to over 75,000 wind turbines inspected worldwide by our technology! We did some analysis of these inspections and thought we’d share a few top-line observations […]

In the Press

POV: Why DaaS beats DIY blade inspections

From the minute they appeared, camera drones joined the arsenal of tools which enterprising site operators use to figure out what’s going on with their wind turbine blades. And for good reason. Buying an off-the-shelf camera drone has become less expensive over time, becoming an expense more easily afforded within existing budgets. A “Do-It-Yourself” (DIY) […]

In the Press

Case Study: Drones with brains and shelves with eyes — digitalizing the physical world

1st November 2018: In the wind energy sector, the usual way to inspect wind turbines is to send a five-person team up each tower. The technicians use ropes and harnesses to make their way up and down the blades, which could be from 40 to 80 meters long. They visually inspect each one while dangling […]

In the Press

POV: Why Clobotics believes that 1+1=3 when it comes to automating blade inspections

This article was first published on the 8th June 2021 As the wind industry matures and the market for external blade inspections continues to expand, automating this essential task is crucial to cost effectively gaining the insight needed to guide maintenance activities and optimize energy production. At Clobotics, we believe that only by investing in […]

In the Press

POV: Making the Case for More Frequent Blade Inspections

This article was first published on the 30th November 2020 All of us who love wind power know that the key to continued adoption is the relentless pursuit of lower costs on two major fronts: initial capital cost and ongoing operations and maintenance (O&M) costs. At Clobotics, our mission is to digitalize, analyze, automate and […]

In the Press

POV: The case for open standards around blade inspections

This article was first published on the 9th February 2021 Today practically all utility scale wind turbines are equipped with SCADA control systems. This has, in turn, paved the way for the advent of Condition Monitoring Systems (CMS), which have seen rapid adoption in recent years. All of this means that data is being generated […]

In the Press

Spring Update

After a dull winter, spring finally arrived! The birds are singing, the flowers have exploded in a sea of colour and our technicians have dusted off their equipment and are heading out on assignments. Our calendar is chock-full of blade inspections and blade repairs both offshore and onshore – what a wonderful time! Autonomous Drone […]

In the Press

Clobotics and ArthWind partner to lead Brazilian blade inspection market

Clobotics and ArthWind announce Drone as a Service partnership

In the Press

Insights Announcement

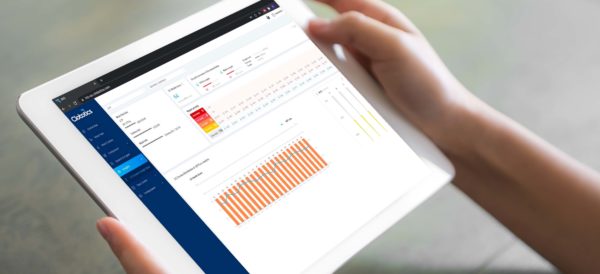

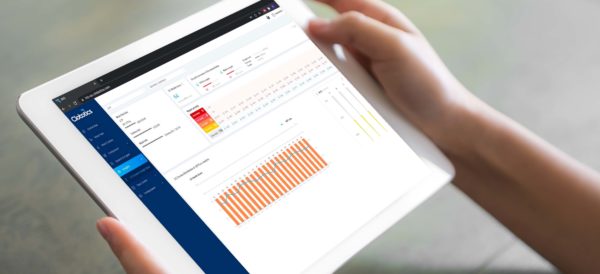

Clobotics Wind Services announces the beta release of the Insights tab in our Clobotics IRIS™ portal for viewing, annotating, and collaborating around visual blade inspection results. Insights adds another, deeper level of analysis to help our customers get the most value from the visual blade inspection data collected by our Clobotics IBIS™ system. This initial […]

In the Press

Clobotics acquires Danish Blade Service to tap wind repair market

October the 28th, 2021 – Clobotics today announces, through its wholly owned subsidiary Clobotics Denmark ApS, the acquisition of Denmark-based Danish Blade Service ApS (“DBS”), a leading independent wind turbine repair solution provider serving customers across Europe. It is the third acquisition Clobotics has made in Europe since 2020 and marks a significant milestone to […]

In the Press

Five Key Takeaways from NRF 2020 Conference

According to a Japanese proverb, “the customer is God.” Yet God’s needs and temperaments are constantly evolving. As must retailers. The annual National Retail Federation provides a huge platform to showcase new solutions and gather industry movers and shakers to predict and shape the retail future. This year’s National Retail Federation conference featured approximately 2,000 exhibitors. It […]

In the Press

Clobotics acquires Finetune to strengthen capabilities in blade expertise and turbine data analytics

Today, Clobotics, announced acquires FinteTune adding significant blade repair and data analytics capabilities to the firm.

In the Press

Clobotics featured as a “Minicorn” in Tracxn’s Top Renewable Energy Tech List

We were honored to make Tracxn’s list of Top Renewable Energy Tech Firms heading into 2020.

In the Press

Clobotics SmartView Cooler Solution Won “The Coca-Cola Company 2019 Global Customer & Commercial Leadership Innovation Award”

We are very proud that Clobotics SmartView Cooler Solution has won the prestigious, The Coca-Cola Company 2019 Global Customer & Commercial Leadership Innovation Award, announced by Coca-Cola Head Office in Atlanta last week. This is the first time in history a technology solution from China wins this global honor. Coca-Cola China and Clobotics have jointly developed this […]

In the Press

Clobotics acquires AtSite to expand its wind industry capabilities

Today, Clobotics, announced acquires AtSite to expand its wind industry capabilities

In the Press

Clobotics COO Claire Chen Featured on CNBC

Clobotics COO & Co-Founder Claire Chen talks to CNBC about the company’s computer vision, AI, and data analytics technology. But how does Clobotics differentiate itself in an emerging marketplace? “We are more focused on solving the last-mile problem for the business.” Watch the entire interview: http://ow.ly/uJXs50xWv9T

In the Press

Clobotics Corp. Receives $10 Million From Tiger Management Fund to Accelerate Growth

Case Study

Drones with brains and shelves with eyes — digitalizing the physical world

In the wind energy sector, the usual way to inspect wind turbines is to send a five-person team up each tower. The technicians use ropes and harnesses to make their way up and down the blades, which could be from 40 to 80 meters long. They visually inspect each one while dangling as high as 100 meters above the ground. Given that these are obviously windy conditions, it’s a dangerous activity prone to accidents.