It’s time, once again, for our End of Year Report – aggregate global statistics drawn from our Clobotics IRIS portal system for organizing, analyzing and presenting blade inspection and repair information.

This year, we look back on nearly 40,000 wind turbines worth of inspections conducted in 2023 across every region of the globe. This brings the cumulative total of inspections done by our Clobotics IBIS™ autonomous drone-based system to just under 115,000 wind turbines since its inception seven years ago.

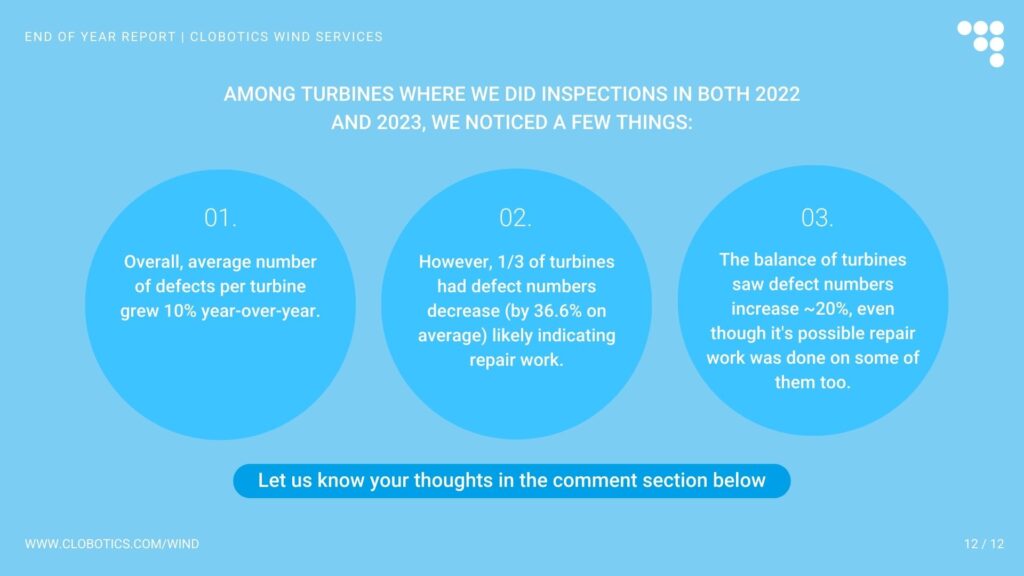

Since this is our second year doing this, we will begin showing trends for those statistics that we also reported in our 2022 End of Year Report. We also introduce several new statistics, including observations about blades that were inspected in both 2022 and 2023. This past year we introduced the Timeline Defect Linking feature in our IRIS™ portal, enabling our customers to track defects over time.

A couple of caveats and notes about this year’s statistics:

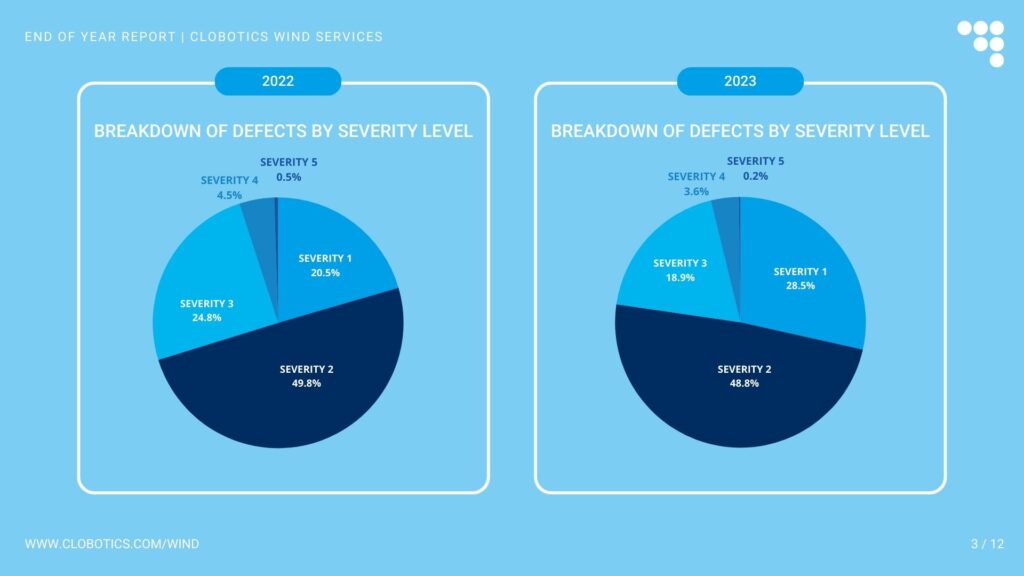

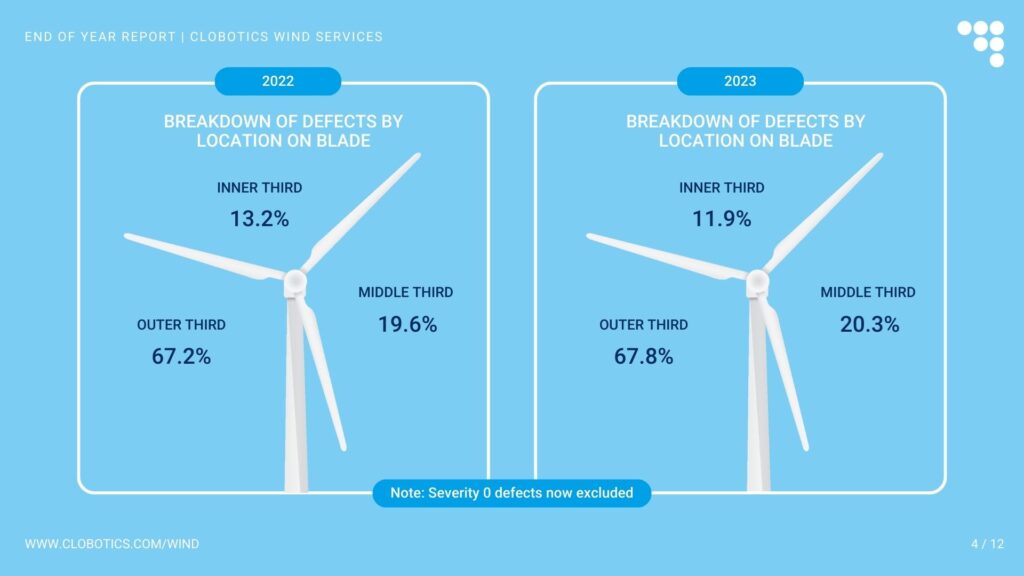

- In the 2022 report, we included Severity 0 defects which some of our customers and partners use to track items they want to check on. We have decided to eliminate those from our analysis this year which will change some of the 2022 numbers we report this year compared to what we reported in last year’s report.

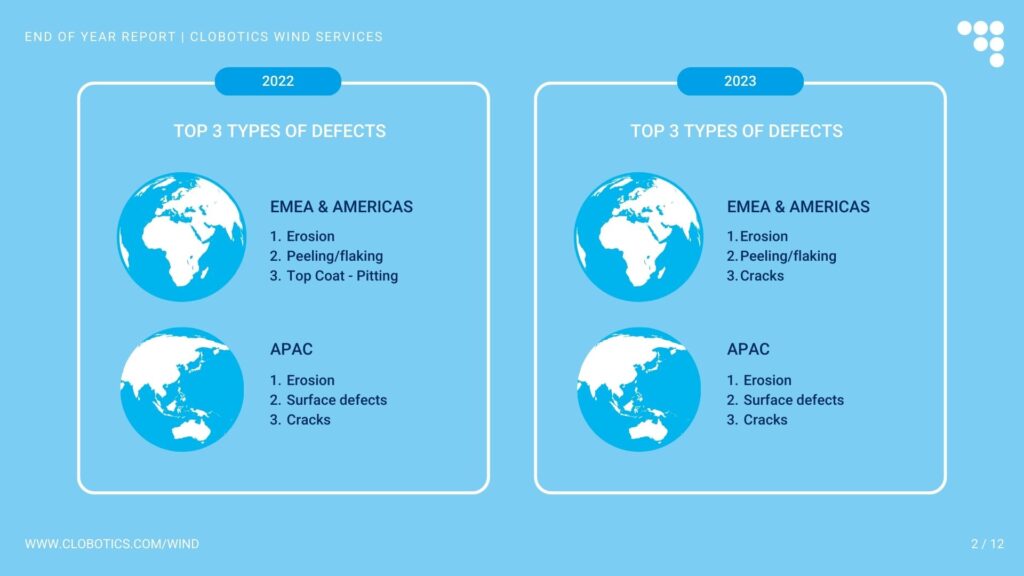

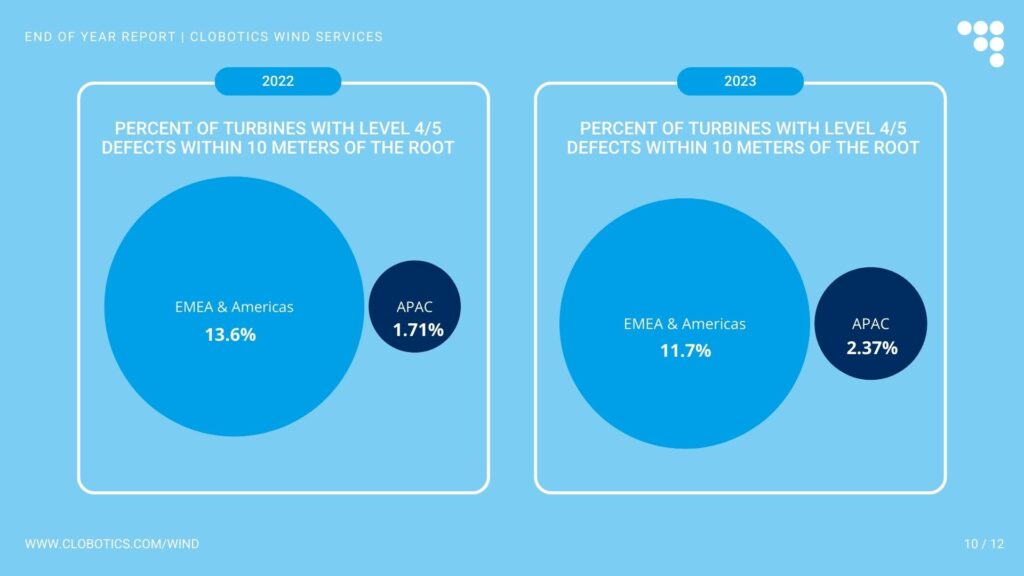

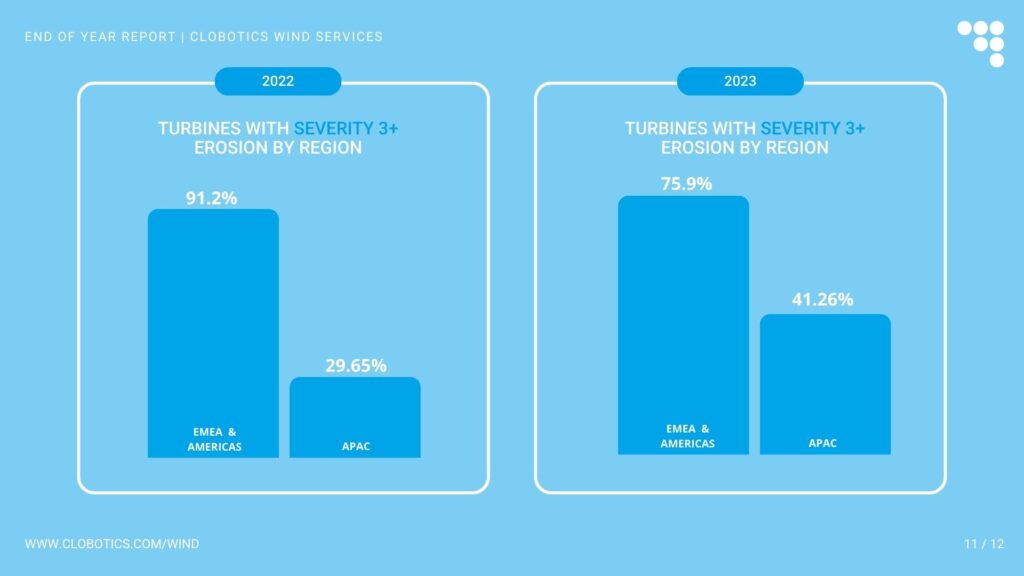

- We notice pretty significant differences between regions in some statistical areas. This may be due to our different mix of OEM, owner/operator, and partner customers in different regions of the world. It may be due to different labeling standards since some of our customers label their own inspections. It may be due to differences in equipment deployed in different parts of the world. Or some combination of all of these things.

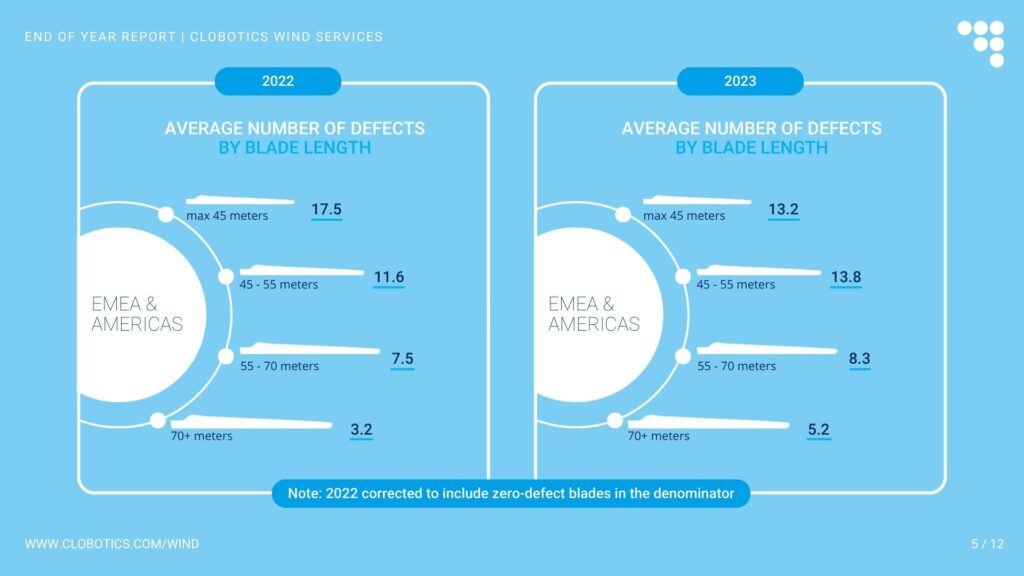

- We found one mistake from our 2022 EOY report that changed the statistic on average defects per blade. In last year’s analysis, we omitted blades with no defects on them from the denominator which significantly overstated the average across all blades. We have corrected this in the 2023 Report and apologize for the error.

- Finally, we want to be clear that these statistics are not necessarily representative of the broad industry since our mix of customer types, equipment brands inspected, onshore vs offshore, etc are unique to Clobotics. With that said, we believe the sheer volume of inspections conducted with our technology makes our aggregate statistics of interest and hope you agree.

Feel free to contact us here with any follow-up questions