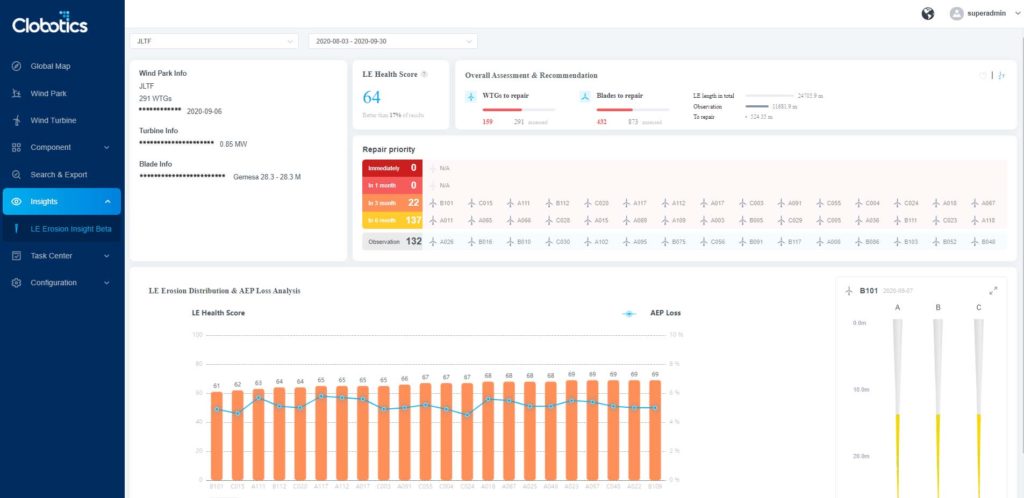

Clobotics Wind Services announces the beta release of the Insights tab in our Clobotics IRIS™ portal for viewing, annotating, and collaborating around visual blade inspection results. Insights adds another, deeper level of analysis to help our customers get the most value from the visual blade inspection data collected by our Clobotics IBIS™ system. This initial release focuses on leading edge erosion, but other defect categories will follow over time.

Traditionally, leading edge erosion is identified from visual blade inspections using the same polygon-based markup that is used for identifying all other blade defects. But erosion is not a discrete phenomenon, and Clobotics machine learning models are able to assess both the area and extent of erosion across the entire leading-edge surface of each turbine blade.

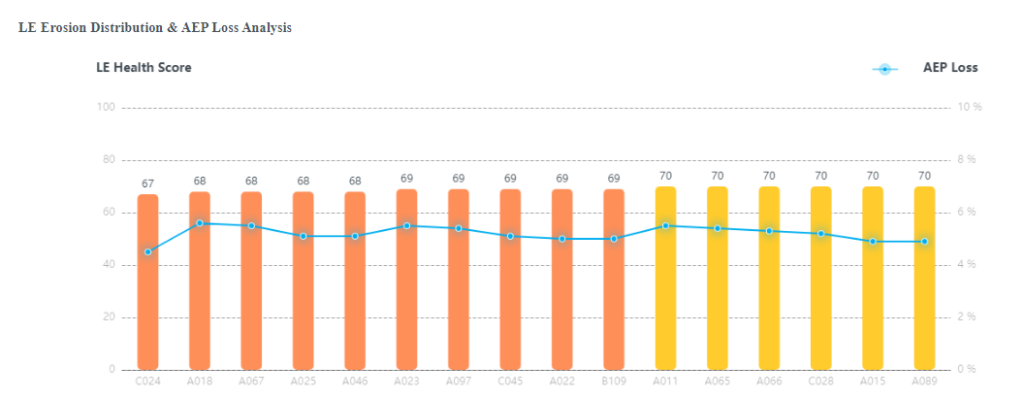

The results are presented in several ways:

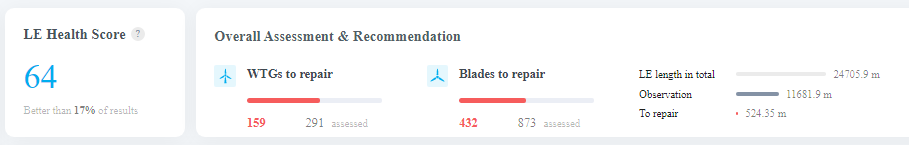

- An aggregate “Leading Edge Health” score that reflects the erosion health of the entire wind park.

- A by-turbine “Repair Priority” classification that goes from “Repair Immediately” to “Observation”

- A per turbine estimate of AEP loss as a percentage of maximum theoretical production

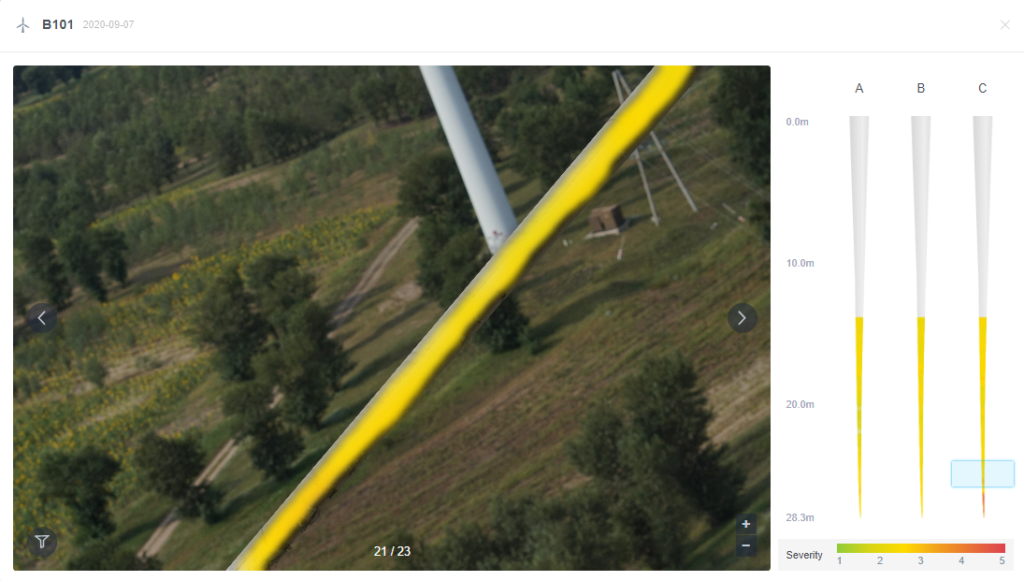

- A visual “heat map” of the extent and degree of the erosion super-imposed on the collected blade images

Insights is exciting because it is a level of analysis that could not practically be accomplished by humans given the depth, extent and precision of image analysis required. It is enabled by the machine learning models that Clobotics has been refining since we first began analyzing visual inspection data nearly five years and over 45,000 wind turbines ago. Clobotics’ goal is a world where people do not have to quality control the results of these models anymore and both the cost and the turnaround time for inspection analysis is so trivial that it becomes a foundational part of how wind park owners manage their assets.

The reasons that this is a beta release are two-fold:

- We are interested in feedback from our customers about both the metrics we are surfacing in Insights and how they can be further refined and integrated with the rest of the analysis in IRIS; and

- Our models are not quite to the level of accuracy that we want to see before calling the results shipping quality.

So, we look forward to interacting with both current and potential customers around this new level of functionality in our portal. To schedule a full demo of our IRIS portal and our new Insights tab, please reach out to us here.