After a dull winter, spring finally arrived!

The birds are singing, the flowers have exploded in a sea of colour and our technicians have dusted off their equipment and are heading out on assignments. Our calendar is chock-full of blade inspections and blade repairs both offshore and onshore – what a wonderful time!

Autonomous Drone Inspections of Wind Turbine Blades

Some highlights from our team of professional drone pilots… On one project, our European team inspected 88 of some of the world’s biggest offshore turbines (9.5 MW) and had a few other major assignments with our own vessel working and staying offshore.

Meanwhile, our North American team inspected an astounding 31 onshore turbines in one day with just one drone and 71 in 3 days on the same project. They also completed a huge 100-turbine project in rural Illinois.

In-house Experts Developing Cutting-Edge Technology

Meanwhile, our in-house engineers are hard at work on optimizing our cutting-edge technologies.

In Denmark, the engineers have celebrated a successful field test of our Top-Secret Project and they continue to improve the product on a daily basis. Clue: it involves a lot of tinkering with actuators.

Despite the lockdown in Shanghai, our Chinese development team have made incredible progress on our IBIS drone and IRIS portal. Our systems are constantly being analysed and upgraded and this wouldn’t be possible without their hard work.

Drone as a Service

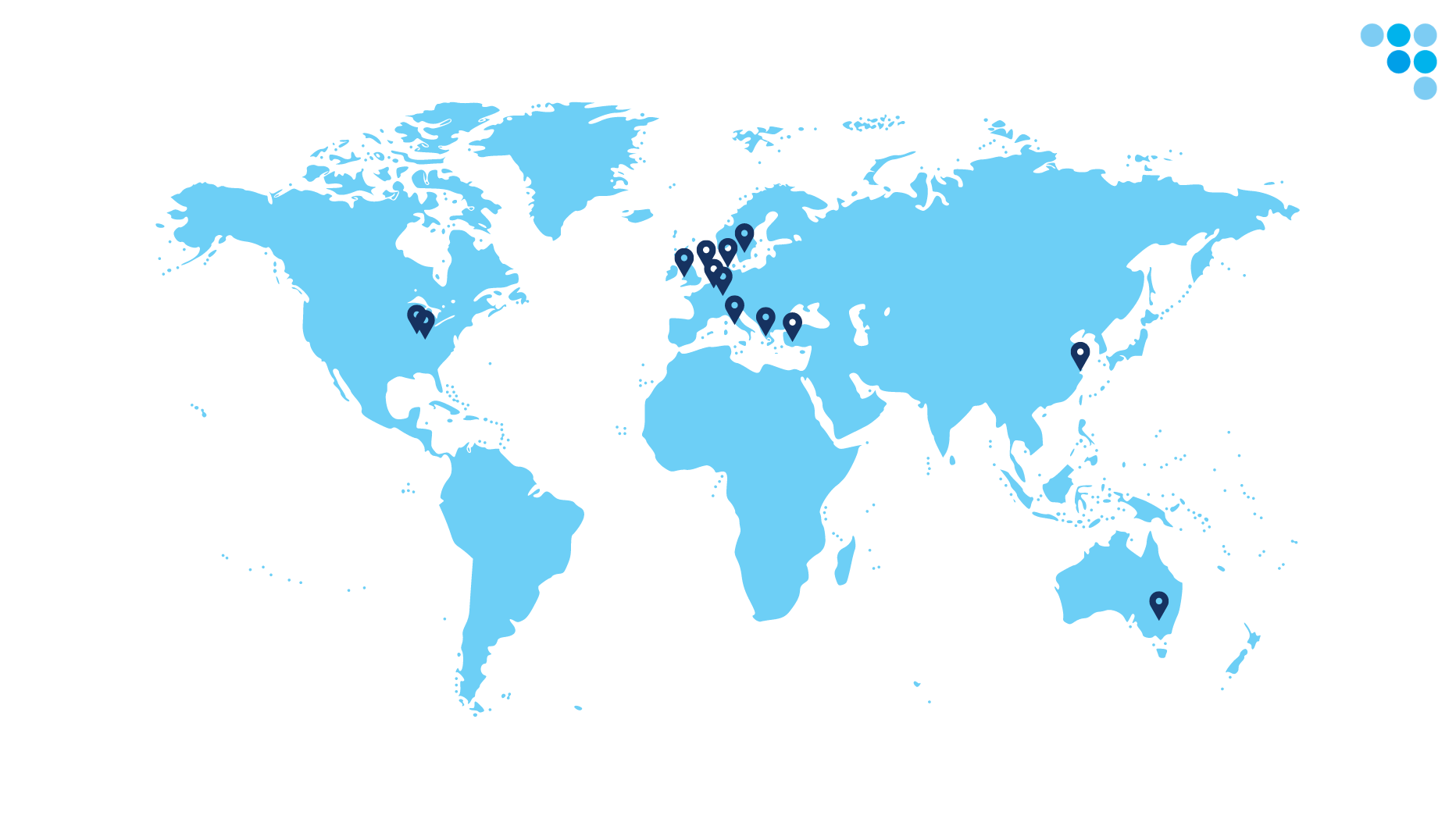

Our brilliant sales team have also kept busy, resulting in a host of new DaaS partners all around the world. We warmly welcome companies such as…

- Susol (Turkey)

- ArthWind (Brazil)

- Zupson Service (Romania)

Repairs

If you didn’t already know, we now have a dedicated repair department and repair season has also begun. Our technicians are away on blade repair projects in Denmark, Germany, and the Netherlands. Some of these jobs utilise our own climate-controlled platform for safe and efficient work. More European blade repairs will commence over summer, including offshore rope access jobs.