Internal Blade Inspections

Internal blade inspections are crucial for a detailed and thorough understanding of the condition of your wind turbine generators (WTGs). Clobotics performs internal blade inspections in a safe and effective way, providing blade specialists trained to work in confined spaces and experienced in using advanced robot crawler systems.

Clobotics offers internal blade inspections performed by blade specialists and a ROV (remotely operated vehicle). The blade specialist performs a thorough close-up inspection, while the ROV operator conducts a remote inspection of the blade tip, where humans are not allowed to enter.

Data from the inspection is uploaded to the Clobotics online portal when a data connection is available. This data is then made available for easy access and report generation.

The highly experienced Clobotics project management team facilitates the complete project management including task-specific planning that accounts for local requirements, confined space work, HSE, tools and procedures.

LPS Testing

LPS testing is an important part of yearly preventative maintenance routines to ensure flawless connectivity from the conductors all the way to the ground. Faulty conductors can have a significant impact on the structural integrity of the blade and, in worst cases, result in complete blade failure.

Clobotics performs tests according to OEM requirements, on the full blade structure and the remaining part of the Lightning Protection System.

Clobotics offers LPS testing performed by rope access or from cherry pickers during the process of performing repairs. A Digital Low Resistance Ohmmeter (the Megger testing unit) is used to capture resistance readings throughout the lightning conductor system. These readings are presented in a .pdf report which is available the following day. The results are compared to blade manufacturer specifications and for any reading that does not meet the requirements, repair suggestions will be provided.

All types of blades risk exposure to lightning strikes. Professional inspections and repairs are imperative to prevent further damage or blade failure.

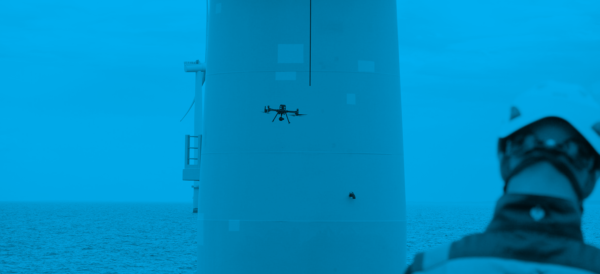

Uptower Inspections

For further assessment of structural integrity, there might be cases where close-up inspections are needed. Uptower inspections can be performed from rope access, cherry pickers/boom cranes or wire-suspended platforms.

Clobotics has a range of cost-effective in-house systems to be able to react fast to inspection requests.

By choosing Clobotics you are certain that all specialists are well-educated and backed up by blade experts.

Uptower inspections can consist of visual inspections, tap testing or other NDT methods (non-destructive testing). Inspections are often combined with LPS testing to meet client needs or regulatory requirements.

In-house Blade Specialists

Clobotics is the safe choice for complicated wind turbine blade cases. We inspect and repair tens of thousands of blades every year and our blade experts have decades of experience in the industry.

By choosing a company with global presence, you can safely place your assets in our hands.

Our in-house blade specialists are used to complicated design assessments, structural assessments, blade production assessments and engineering of repair procedures.