Aerodynamic optimization using Vortex Generators

VGs (Vortex Generators) are a commonly known technology that can increase power production by 2-4%. Over the years, leading edge erosion and dirt can result in gradually decreasing energy production, but by adding VG’s the airflow along the blade surface is energized which improves the aerodynamics and, in turn, the energy production of the turbine.

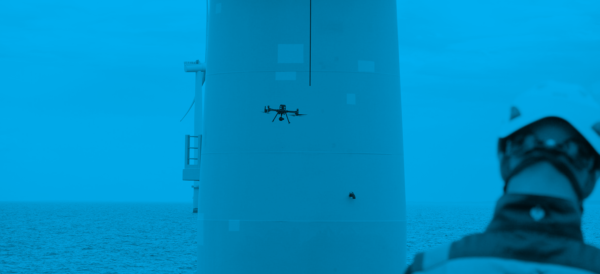

Clobotics delivers the entire scope of this service. Blades are 3D modelled and analysis is performed based on individual blade type and size.

We also have in-house specialists who can successfully apply vortex generators as part of repair projects or LEP application projects.

Material Development

We are continuously working on material technologies and improvements of work methods using our decades of operational experience. As a market leading technology company, we lead the development of materials for faster application and for improving the performance of turbines. Development projects are initiated by Clobotics internally but pursued in cooperation with leading specialists in the wind industry.

During our repair work, we capture all relevant data using our Clobotics Raven technologies so our blade experts can closely follow material behaviour in the application phase and material deterioration in the years following application. Raven ensures that all environmental data, cycle times and paint intervals are accurately logged.

Materials are tested in our facilities in Denmark in collaboration with accredited testing firms. As an operational repair company, we sign early adoption agreements with operators for testing materials and their duration on live turbines in the early stage of development. This ensures an extremely fast development cycle where products are rapidly perfected for mainstream operations.