Structural Repairs

Clobotics are a trusted, ISO-certified partner for all categories of repair. With a range of in-house blade specialists, we can perform the most advanced repairs. Our blade experts assess the specific defects and choose relevant work instructions to ensure the highest quality of work.

When we plan repairs, the optimal repair methods and access options are chosen. We choose access methods between rope access/act safe, cherry pickers, a wire suspended platform or bringing the blades to ground. Bringing blades to the ground to do repairs in a tent are naturally the last option due to cost and turbine downtime but can in some cases be the best option to ensure a high-quality result.

We use Clobotics Raven technologies to track our repair work. Raven optimizes the workflow of repair technicians and ensures that all repair steps are being captured automatically and produce accurate data for reporting and online access.

Material Technology

Over the last 12 years, our repair team has developed and designed materials and repair technologies to improve repair strength, weather limits and operational aspects. These materials and methods are widely used and the reason for Clobotics’ success in repairs. We are constantly developing new systems to improve our operations and competitiveness. We have a unique opportunity to develop in-house technologies because of our team of blade experts and engineers.

We have developed repair methods for carbon fibre based de-icing systems. The enhanced de-icing repair is considered more stable than the initial validation repair and the entire laminate transfers the heat. The system is proven in laboratories and has been applied on turbines since 2020.

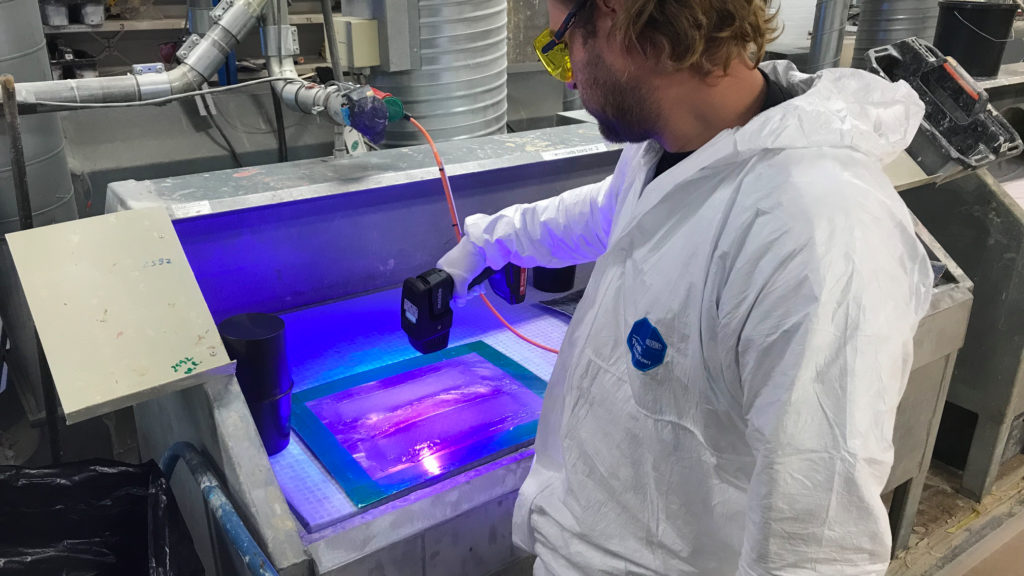

To optimize repair speed, Clobotics has developed a ground-breaking ultraviolet (UV) curing resin. This method has been developed and tested in collaboration with the Danish Technology University. The result is a repair method that allows repair in –10°C temperatures and humidity up to 90%.

Spare Parts Stock

Uptime of turbines is crucial and even the small parts can stop production. Therefore, we have a large and comprehensive stock of spare parts for a large range of blade types, including obsolete and hard to find spares.

At our warehouse in Denmark, we safely store mechanical parts and materials which are shipped to our field teams or clients directly. With our strong supplier network, we are always capable of sourcing spare parts and special materials.

In our warehouse facilities we repair and maintain parts and perform testing prior to installation.

And as part of signing blade service agreements, we can maintain a client-dedicated safety stock ensuring a one-day response time.

Automating Repairs

Clobotics is actively working on developing repair robots to cut down on repair time and thus optimize the energy output of wind turbines.

We combine our global knowledge from thousands of drone operations onshore and offshore with our market leading repair experience and superior software development competencies.