We recently completed our look back on a very successful 2022 inspection season around the world.

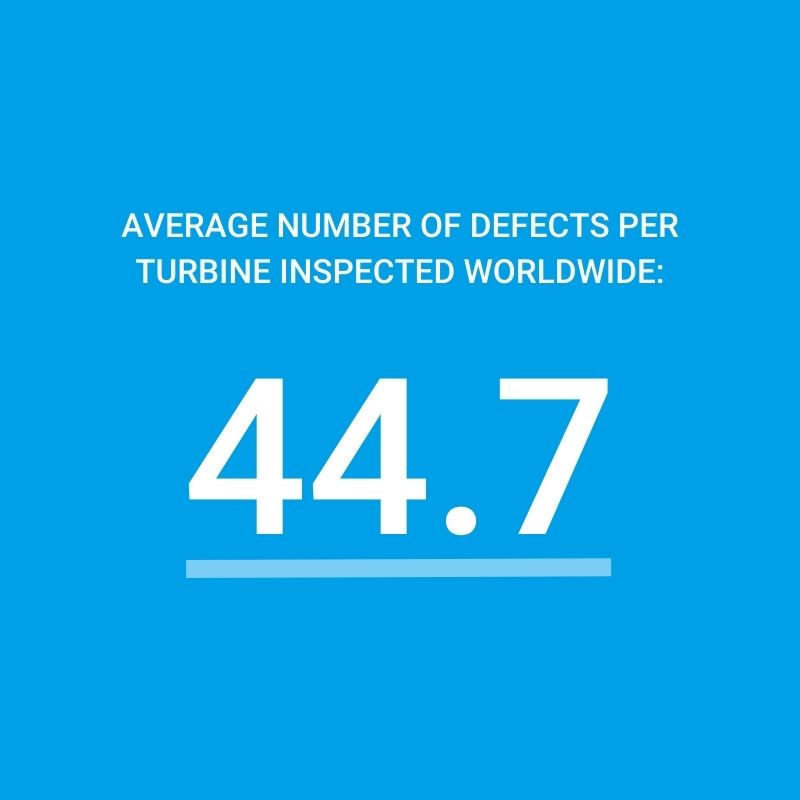

Across our global regions, we inspected over 32,000 wind turbines bringing the cumulative total to over 75,000 wind turbines inspected worldwide by our technology!

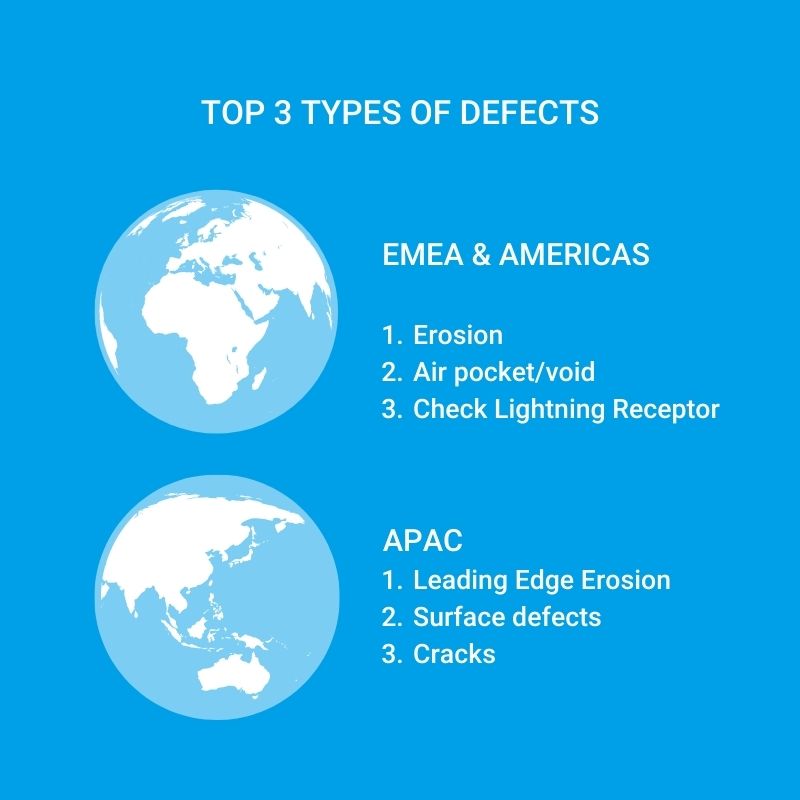

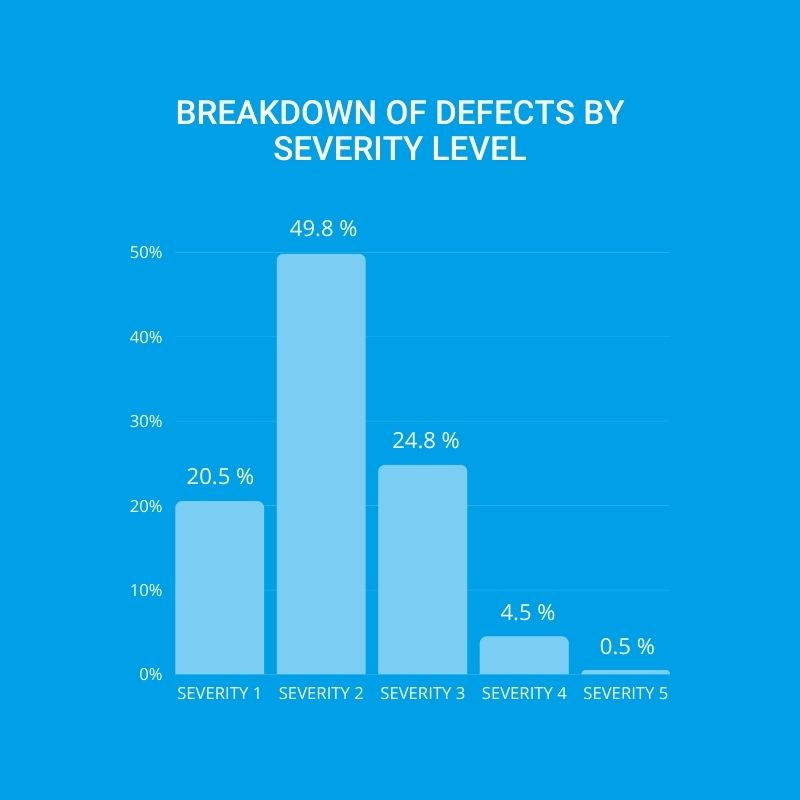

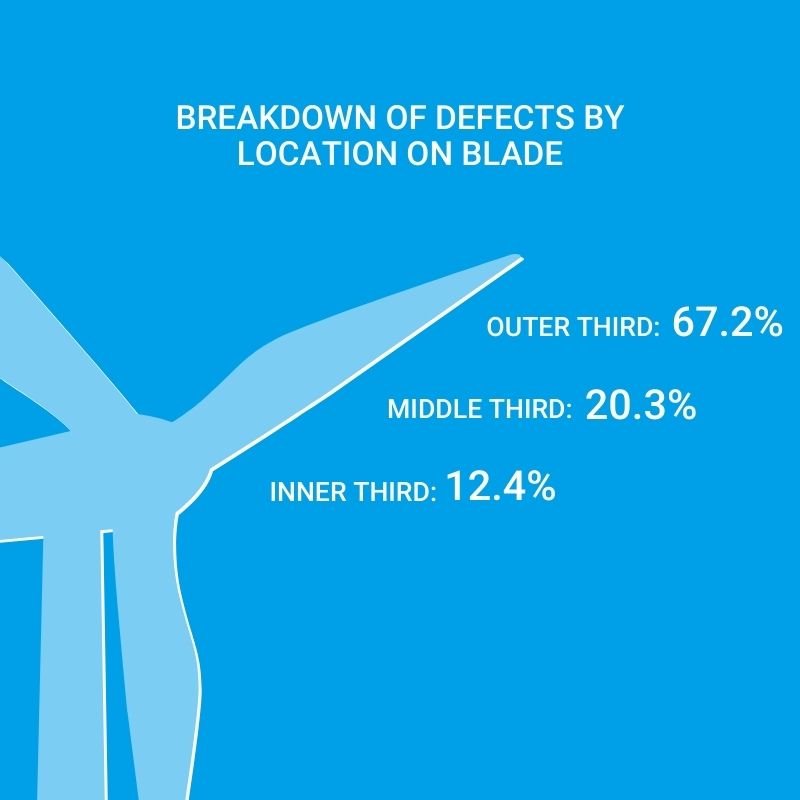

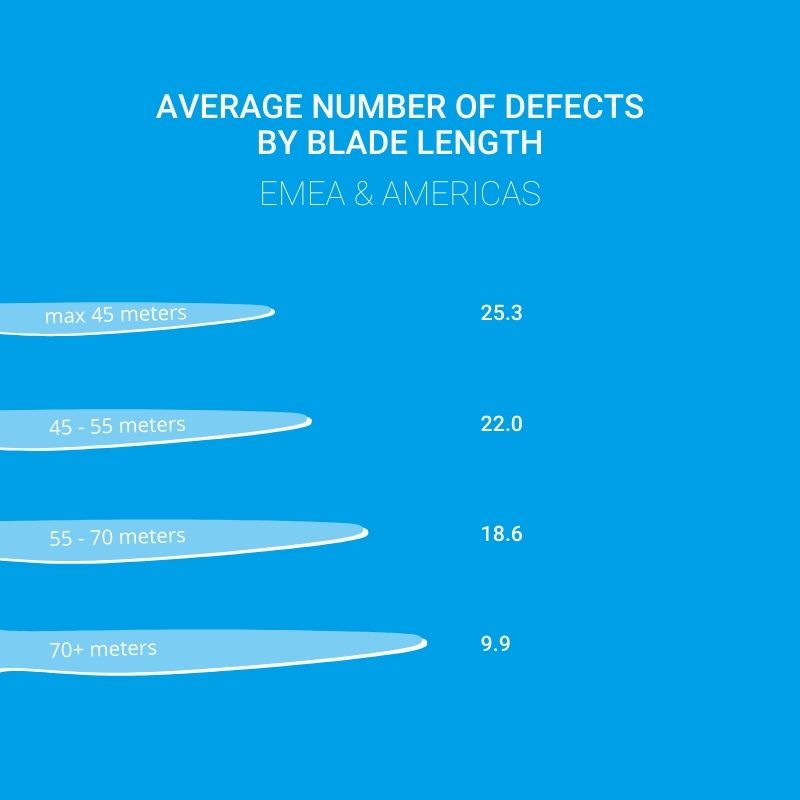

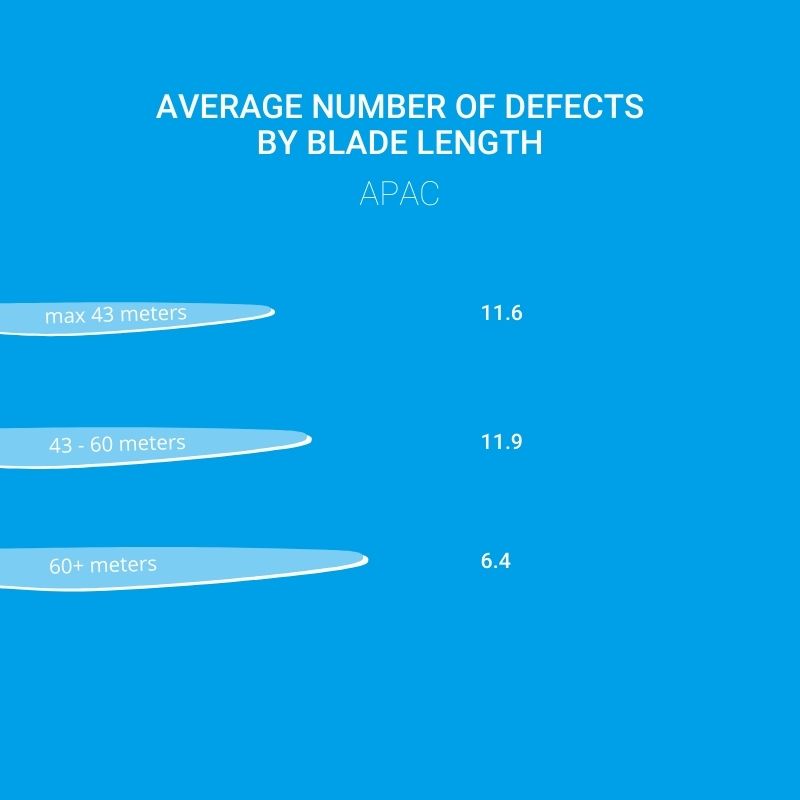

We did some analysis of these inspections and thought we’d share a few top-line observations from the thousands of wind turbines inspected and the hundreds of thousands of defects identified.

There are no huge surprises to us in these numbers, but since they represent actual data collected around the world last year, we thought you might find them interesting.

Feel free to contact us here with any follow-up questions