This article was first published on the 30th November 2020

All of us who love wind power know that the key to continued adoption is the relentless pursuit of lower costs on two major fronts: initial capital cost and ongoing operations and maintenance (O&M) costs. At Clobotics, our mission is to digitalize, analyze, automate and predict to empower our wind customers to lower maintenance costs and increase annual energy production (AEP).

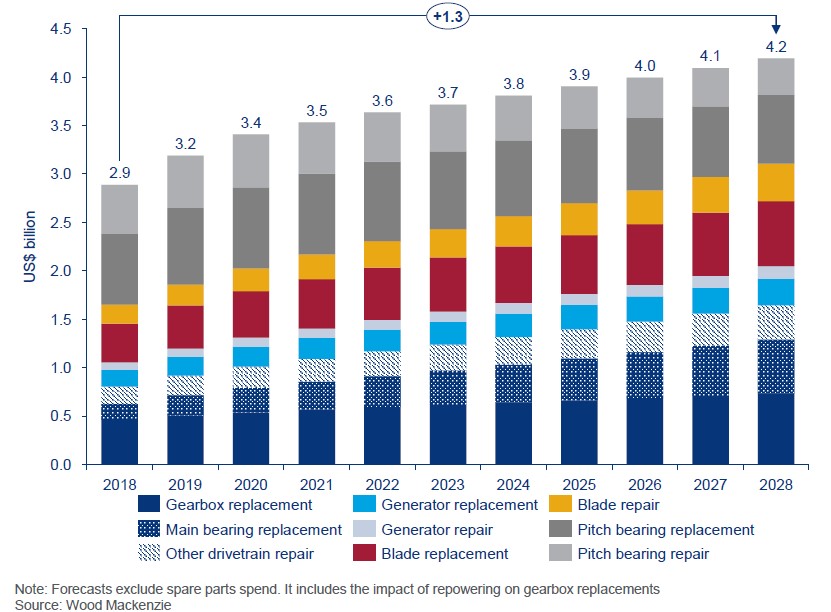

Turbine blades turn out to be crucial in this mission both because they represent one of the largest categories of maintenance costs, and because their condition has a direct impact on how much energy the wind turbine can produce. While sensor data and information from the turbine’s Supervisory Control and Data Acquisition (SCADA) system can provide clues about a turbine’s blade condition, there is no substitute for a visual inspection.

Five years ago, visual inspections were largely manually done. They were dangerous and expensive in both labor hours and lost energy production. As a result, they were done infrequently and generally poorly documented. Custom-programmed, autonomous drones have dramatically changed the landscape on visual blade inspections, eliminating the danger to personnel and making huge strides in both data quality and collection cost. In fact, the improved quality and consistency of the data feed enabled by automatic image capture makes it feasible to build fully automatic processing pipelines based on machine learning, resulting in very rapid turnaround from inspection to results and recommendations.

Because of all of this innovation, we believe there is a business case for wind turbine owners and operators to significantly increase the frequency of blade inspections.

One example of how this pays off is by more closely monitoring leading edge erosion. Erosion is a progressive degradation mechanism that affects asset integrity as well as aerodynamic performance. It is the most expensive item in the O&M schedule, and there is a lot to be gained by timing the repairs right, choosing the right materials and repair processes, and deploying AEP loss mitigation strategies such as aerodynamic add-ons or control adjustments. Our Image Recognition and Insights System (IRIS™) erosion mapping service provides the data feed that is the basis for planning optimal repair campaigns.

Wout Ruijter was Principal Engineer at Clobotics

Other Point of View Posts:

- The case for open standards around blade inspections

- Why Clobotics believes that 1+1=3 when it comes to automating blade inspections