This article was first published on the 9th February 2021

Today practically all utility scale wind turbines are equipped with SCADA control systems. This has, in turn, paved the way for the advent of Condition Monitoring Systems (CMS), which have seen rapid adoption in recent years. All of this means that data is being generated and used extensively in the operation of and maintenance planning for wind turbines.

The industry does have a uniform information exchange standard for monitoring and control of wind power plants. This is known as IEC 61400-25 and was first released some 15 years ago in 2006. The standard provides the possibility to design interoperable products and systems, but there is more work to do.

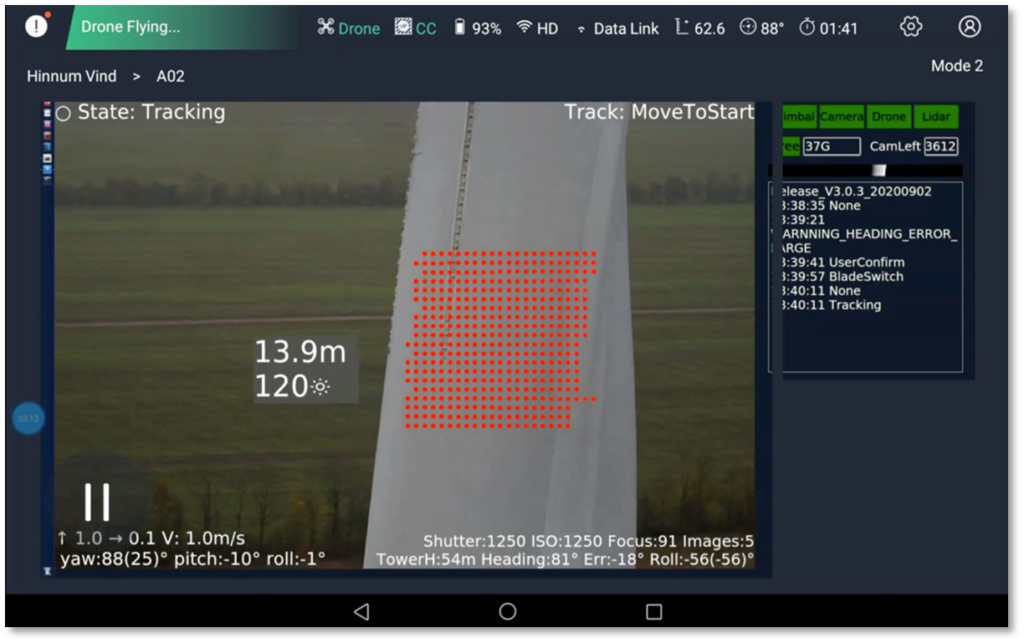

Specifically, in the blade area, visual inspections done by automated systems like our Clobotics IBIS™ drone are capturing hundreds of high-resolution images per turbine and are rapidly becoming the default method for assessing blade conditions. At Clobotics we believe operations can be improved through significantly more frequent blade inspections as outlined here. And we are working towards the goal of having blade inspection images as an established and standardized data stream which feeds into the turbine condition monitoring system on equal terms with the established data channels. Where are the obstacles?

One obstacle is that the established standard is centered around a SCADA data system and image data is normally not considered as a data channel. With machine learning inference used to determine class and location of all blade defects, this will change. At Clobotics we are close to the goal of fully automated evaluation of inspection image data. Soon the image data stream will be condensed and aggregated into tables of fine-grained classifications of blade defects. It will be possible to use this condensed defect overview to feed into the condition monitoring system and both aid the maintenance planning but also serve as important information for the diagnostics of performance optimization.

Getting there requires a cross industry collaboration to establish an open standard for the data stream. This includes specifications for:

- Image data

- Defect types

- Severity assessment

- Evaluation methodologies

Another valuable benefit of progress here is that it will reduce the likelihood of “vendor lock in” by inspection suppliers that aim to store their customers’ data in a proprietary portal with no possibility for exporting the data or interfacing it to other important line of business systems.

For Clobotics, the case for an open standard for blade visual inspections is compelling. The technology framework is maturing rapidly with important cornerstones such as autonomous drone flight for image capture and machine learning models for defect evaluations already established. Consistent and objective data capture and evaluation is available, so the time for developing a uniform information exchange standard for blade visual inspection data is now.

Lennart Kuhlmeier is Principal Blade Engineer at Clobotics

Other Point of View Posts:

- Making the case for more frequent blade inspections

- Why Clobotics believes that 1+1=3 when it comes to automating blade inspections